Manufacturing companies are reliant on uniformity, coordination, and control. Any late material, ambiguous inventory, and communication breakdown between suppliers results in inefficiency in production. This is the reason why manufacturers increasingly look toward top supply chain management companies to create stability and long-term operational strength.

Modern supply chain partners do not merely concentrate on logistics; instead, they assist manufacturers in building systems that enable planning, execution, and continuous improvement. Most of the winning manufacturers today work with companies with supply chain management expertise that extends beyond basic coordination and into strategic operational support.

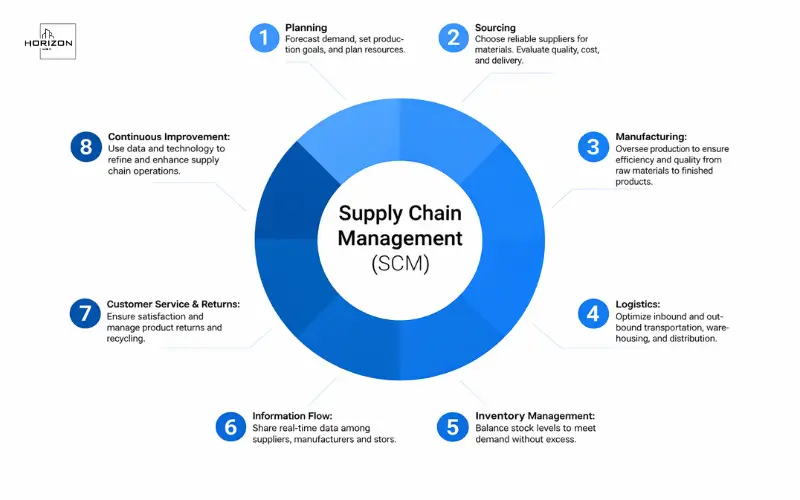

The Supply Chain Management in Manufacturing

The manufacturing supply chains integrate sourcing, production, inventory, and the coordination of suppliers into a single process of operation. It is critical to align with the next stage as it influences it.

Why Supply Chain Management is essential to Manufacturing.

Production is based on time and precision. The right materials should be supplied at the time they are needed in production. Inadequate coordination tends to result in the piling up of inventory, sourcing decisions, or even stagnation in production.

Best supply chain practices involve companies in the aspects of predictability and process discipline. They aim at eliminating uncertainty and establishing a smooth flow of operations in manufacturing activities.

The difference between the Manufacturing Supply Chains and other industries

Production dependencies and quality requirements make manufacturing supply chains more complicated. When there is a delay at a point, it may affect several production stages.

This is what makes it a complex issue, why manufacturers often partner with companies with supply chain management experience specifically tailored to manufacturing environments.

What characterises the best Supply Chain Management Companies in manufacturing?

Service providers do not provide the same degree of impact. Top supply chain management companies manufacturing share core characteristics that support both efficiency and resilience.

Process-Driven Operational Models

Well-established supply chain partners are based on the paperwork and not on response operations. All operations have a set of procedures, which enhance systematization and minimize mistakes.

Companies with good supply chains prioritize structure because it allows manufacturing operations to scale without losing control.

The major advantages of collaborating with companies that have good supply chains are

The manufacturing companies seek collaboration with supply chain companies, which have experience, in order to enhance the daily activities and performance in the long term.

- Enhances sourcing, production, and inventory coordination.

- Eliminates time wastage due to a lack of planning or communication gaps.

- Improves transparency in the supply chain.

- Enhances cost management by the use of formal procedures.

- Enables the internal teams to concentrate on strategic decisions.

These advantages are the motivations behind the trend whereby all manufacturers are turning to companies that have the best supply chain practices instead of doing everything on their own.

Basic Services of Supply Chain Management Companies

Learning about the scope of service assists manufacturers in assessing how a partner fits into the operational requirements.

Supplier Coordination and Communication Support

Management of suppliers, documentation, and follow-ups is done by the supply chain management companies. This enhances uniformity as well as minimizes the internal administration burden.

Companies with good supply chains emphasize reliable supplier coordination to prevent disruptions.

Material Flow Alignment Production Planning

A good supply chain management is that which matches the availability of materials and the production schedules. This makes sure that production will go on unimpeded.

Companies with supply chain management expertise focus on synchronization rather than reactive sourcing.

Inventory Planning and Control

Equity inventory is critical to efficiency in manufacturing. Stockpiles lead to higher expenses and shortages in production.

Best supply chain systems result in companies having well-structured planning to hold the best inventory levels of their operations, depending on the actual operational demand.

How Manufacturers Use Supply Chain Management Support

The way manufacturers interact with their supply chain partners depends on the size and growth level, as well as the complexity of the partners.

Scaling Operations Without Internal Overload

Internal teams tend to have more coordination pressures as the manufacturing operations increase. Outsourcing offers a scalable support without internal complexity.

This will enable manufacturers to expand and, at the same time, remain in control and visible.

Improving Accuracy in High-Volume Manufacturing

The environment in manufacturing has high volumes of data. Sourcing or inventory errors can easily get out of hand.

Firms that have the skills in supply chain management introduce organized mechanisms that enhance precision and uniformity in all operations.

Capabilities to Look for in Companies With Supply Chain Management Expertise

When deciding what partner to choose, price is not the only criterion that should be considered.

- Good documentation of workflow and process discipline.

- Credible information management and reporting.

- Especially active detection of working problems.

- Demand responsive flexibility models.

- Open and uniform communication.

These capabilities are common among companies with the best supply chain performance.

Technology and Data in Modern Manufacturing Supply Chains

Technology assists in the efficiency of the supply chain, but it has to be effective.

Data Visibility and Reporting Clarity

Clarity of data assists manufacturers in making good decisions. Companies with good supply chains prioritize meaningful insights rather than excessive reporting.

Better visibility supports proactive planning and faster issue resolution.

Data Security and Operational Trust

Manufacturing supply chains entail delicate operational information. Reliable business partners have stringent data protection measures.

When dealing with companies that have a supply chain management role to play, security is one of the factors that can be considered.

Common Use Cases for Manufacturing Supply Chain Support

There are such cases when manufacturers need some outside help.

- In periods of fast expansion of operations.

- Coordination is overloaded in internal teams.

- Complex or large-volume sourcing conditions.

- In situations where there is low visibility between operations.

- At the same time as enhancing long-term supply chain resilience.

Such situations demonstrate the expediency of good supply chains in companies.

Mistakes to Avoid When Choosing Supply Chain Partners

Choosing a partner with poor qualities can make things less efficient and less efficient.

Choosing Cost Over Capability

Low-cost providers are not as mature in their processes. It causes latent expenses in terms of delays and mistakes.

Manufacturers benefit more from companies with the best supply chain discipline than from short-term savings.

No consideration of Long-Term Scalability

A partner that would not scale with growth in manufacturing will be a limitation. The long-term compatibility must always be put into consideration.

The reason Strategic Alignment is the most important issue in any given size.

Not all the largest ones are the best supply chain partners.

Understanding Manufacturing Priorities

Firms that have expertise in supply chain management take time to get to know the production restrictions and expectations.

Such knowledge results in improved operational congruence and performance.

Collaborative Partnership Approach

A powerful supply chain is established through partnerships and not transactional relationships. Alliances that serve as external extensions of internal units are more value-creating over the long term.

Long-term Effect of cooperation with the companies having the best supply chains

The appropriate supply chain partner has a longer-term impact on the performance of manufacturing.

Sustainable Efficiency Improvements

Structured processes and constant optimization result in permanent efficiency improvement as opposed to temporary remedies.

Greater Operational Agility

Agile supply chains are responsive to changes in demand. Good supply chains in companies ensure that manufacturers are not interrupted.

Final Thoughts

Choosing among the top supply chain management companies for manufacturing is a strategic decision that shapes efficiency, stability, and growth. The manufacturers that collaborate with companies with expertise in supply chain management enjoy better coordination, transparency of vision, and enhanced operational control.

In the case of manufacturing companies that need consistency without overloading internal resources, exploring partnerships with companies with good supply chains can be a practical step toward more resilient and efficient operations.

Frequently Asked Questions

What do top supply chain management companies focus on most?

They are concerned with the consistency of processes, their visibility, coordination with suppliers, and continuity in production.

Are companies with supply chain management services suitable for growing manufacturers?

Yes. They provide scalable support without increasing internal workload.

How soon can manufacturers see improvements?

The gains are usually realized in the initial few months, particularly in the visibility and coordination.

Can supply chain services be customized?

Yes. The best supply chain works in companies that modify processes to suit manufacturing workflows.

Does supply chain management support a long-term solution?

When it is properly aligned, it promotes short-term efficiency as well as long-term resilience.